Inspiration for art can come from anywhere and anything. For one client, blue birds were the starting point for their imagination to dream up this blue bird pendant. Her husband noted that every time she saw a blue bird, it reassured her that things in life would be okay; so he decided to gift her a blue bird for their anniversary.

This piece was made with three metal types, and an eye of exquisite detail that comes only from decades of experience. Starting with the 3D rendering, we knew it was important to get each detail precise. In a project with so many pieces that come together, even the smallest imperfection would cascade into a mountain of errors that would not be easily corrected after casting.

Casting is already a very precise procedure, and this project is a fantastic example of why it has to be done exactly right each time. Because of the different metals used in this piece, there were multiple iterations of the casting process, each with their own specifics for melting temperature, time in the heat, and chemistry makeup. The bird’s legs, body, wings and head were all made of different metals and had to be treated like different projects. While the basics of casting are the same, the details for making sure the metal comes out clean and workable are very different. If one of the bird’s parts wasn’t right, even by a few millimeters, assembly would have been impossible and we’d have to start the creation process over again.

Once the bird’s pieces were cast in their respective metals, it was time for them to be cleaned and assembled. The preliminary cleaning happens pretty quickly: this allows the artisan to double and triple check the pieces for any imperfections, and this is when the rough looking cast pieces turn bright and shiny – and most importantly ready for assembly. Our master craftsman is then able to put the bird together. After some time under the torch, the little guy is complete and ready to once again be cleaned and sent to the stone setter for everyone’s favorite part: the diamonds.

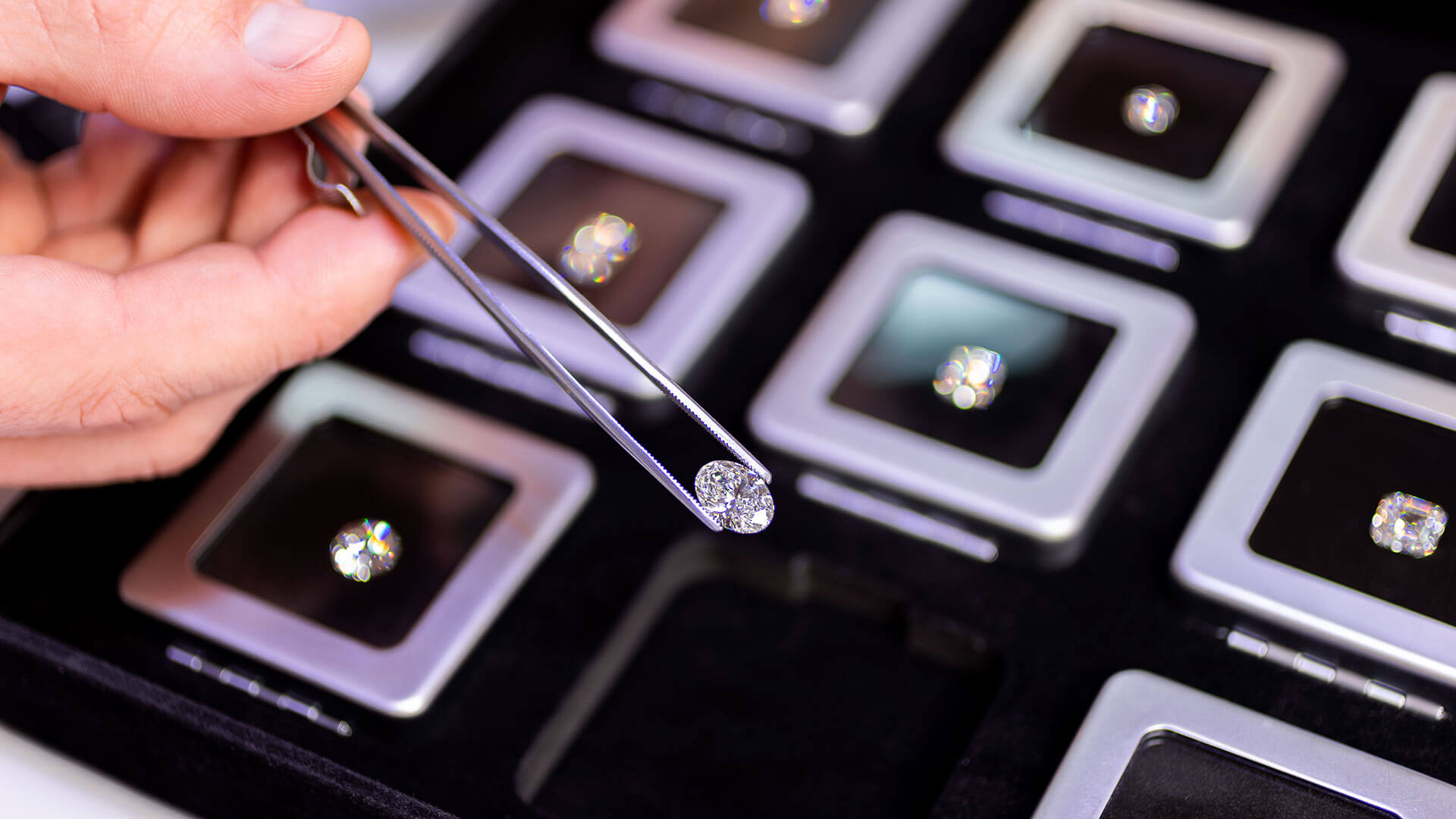

The customer wanted a very specific blue color for their bird, and so it was set with irradiated blue diamonds. The stones each have a specific spot, which we know are correct down to the millimeter because of our 3D model. Dozens of tiny gems are placed over the course of a couple hours (it’s a very time consuming process regardless of skill level) and the setter can finally take a deep breath of relief – it’s another job done perfectly. Our bird friend shines and is almost ready to take flight, they just need a final polish and inspection from Jewelry Designs’ experts. It’s all part of our process to make sure each and every piece that is created in our shop meets the highest standards – and your expectations.

Creating art is our passion; and while we are always working to bring you new and exciting pieces, we also love being able to build jewelry that you won’t find anywhere else. This piece in particular reminded our veteran jewelers of the magnificent Treasure Trove collection that we created nearly twenty years ago. To this day it’s still an inspiring set of some of the finest work. If you have an idea for something unique, visit our showroom to talk with our artisans and start your Jewelry Design journey today.