Jewelry Mold Making

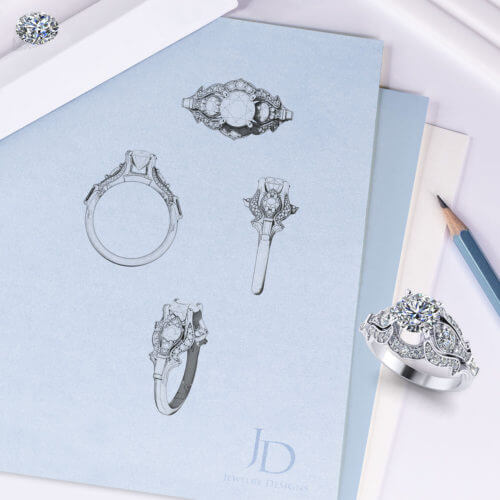

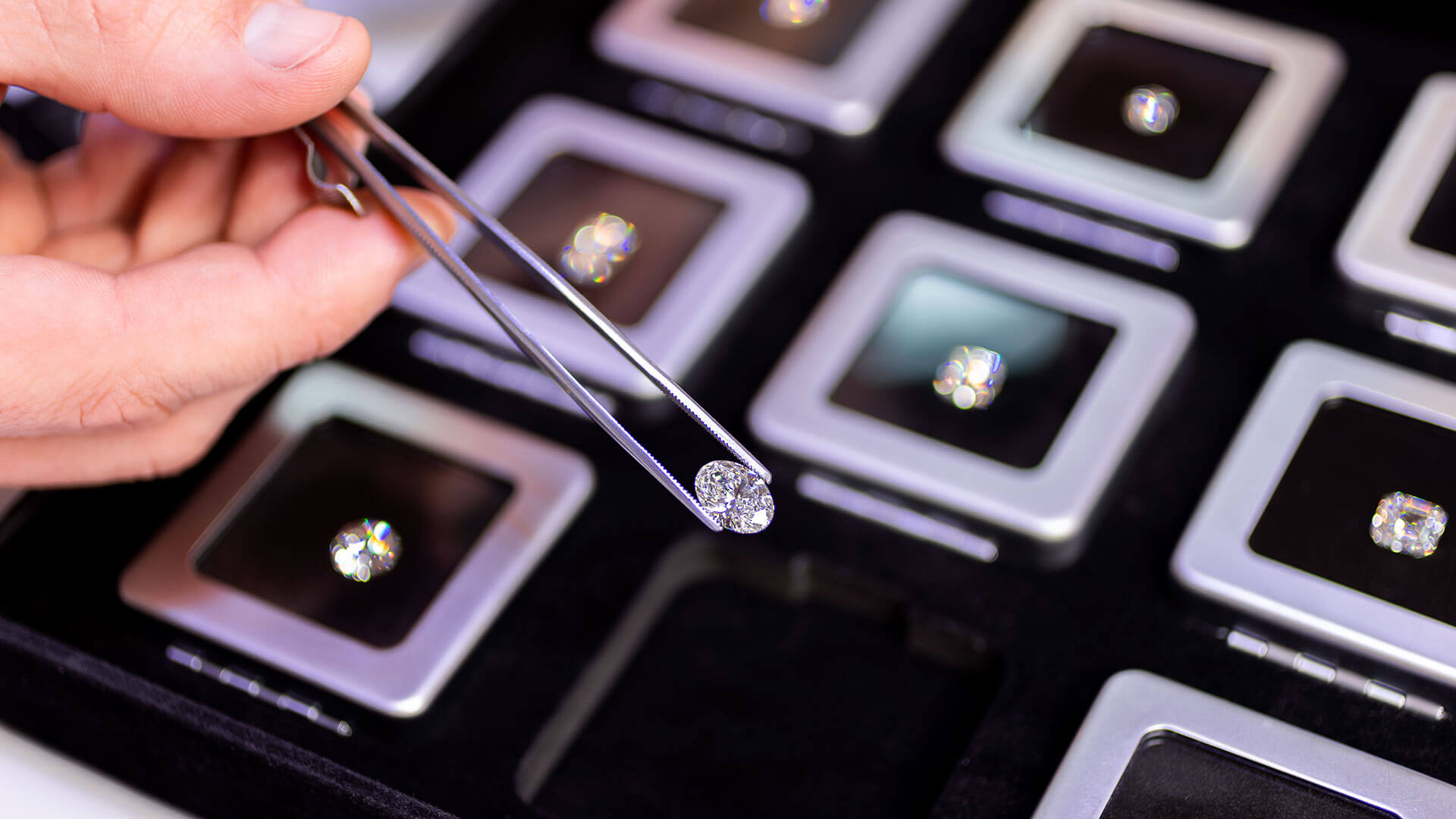

Jewelry Mold making is the procedure used to insure that jewelry items can be accurately duplicated at any time future. The mold making process begins with the creation of a metal model. Models can be as simple as a basic ring or complex as jewelry containing multiple interlinking parts used to create elaborate multicolor jewelry.

The original metal models are crafted from handmade jewelry or cast designs produced by wax carving or cad jewelry design. Once prepared, these models will have a short brass rod shaped sprue soldered onto them. The model is then suspended in a metal frame, packed with uncured rubber and the sprue rod exiting the mold. The frame will then be heated under pressure to vulcanize and cure the rubber around the imbedded model.

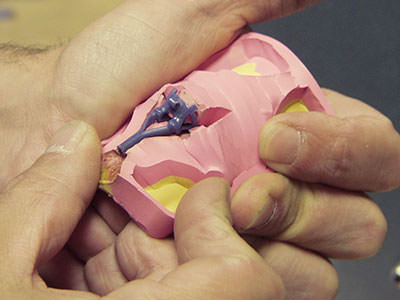

The resulting mold appears as a block of rubber that contains a negative impression of the jewelry enclosed. Once cured and cool, the mold is cut open using surgical knives to release the model within. Once the metal model is released the mold-making cycle is completed by injecting pressurized molten wax through the sprue opening in the rubber mold. Once the wax cools the rubber mold is peeled open to reveal a wax like that of the original jewelry model. When properly cut, a flexible rubber mold will allow the delicate wax to pull freely with minimal distortion.

Waxes that have been injected in molds need to be trimmed and cleaned by jewelers before they can be used. The injected wax models are relieved of flashing, and touched up with spatulas and wax instruments in preparation for the jewelry casting procedure. There the waxes will be encased in plaster. Once cured the plaster will be incinerated to create a cavity in which precious metal will be poured to transform them into precious jewelry. The jewelry mold making process makes it possible for jewelry manufacturers to insure consistent product design.